| South Coast Foam Shapes is dedicated to

maintaining its position as a leader in the foam shape and coating

market through a staff of highly trained and motivated

people sharing a tradition of service and integrity to its

clients. |

|

|

|

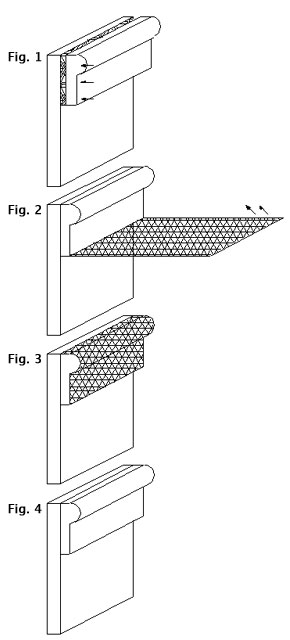

Installation: Foam Shapes To Brown Coat

Fig.1:

An approved primer adhesive is applied directly to the foam shape

using a 3/8" notched trowel. After wetting the brown coat to reduce premature drying of the adhesive, place the shape 2" from its final location. Using a sliding motion move the shape into place insuring good adhesion.

Fig.2:

Upon setting of the adhesive, apply an approved mesh to the shape, lapping the mesh onto the brown coat 1 1/2" top and bottom.

Fig.3:

Trowel an approved basecoat into the mesh using sufficient pressure to bond the mesh to the EPS shape. At installer's option, a second base coat can be applied for further impact resistance. Feather the mesh into the brown coat with the base coat to insure a quality installation.

Fig.4:

At this stage a standard finish can be applied.

NOTE: If the base coat is too smooth, de-lamination may occur.

Always leave the base coat "rough" for a good mechanical bond.

Various application procedures are used in the field of construction. This example is given for your information. We do not warrant any

application procedure as opposed to another, rather we offer this as a suggestion only.

|

© Copyright 2011 South Coast Foam Shapes All Rights Reserved

|

|

|